Waste Recycling

Keyword Navigation

- Excess Sewage Sludge Recycling

- Small Quantity Sludge Recycling (Plant / Agricultural Sewage)

- Ethanol Formation from Waterweed / Corn Cobs (Primary Waste)

- Air Operation System (AOS)

- α-Gaia (Decomposition and Powderization System for Organic Waste)

- Six Merits of Methane Power Generation

- Energy-Saving & Sludge Reduction Wastewater Treatment

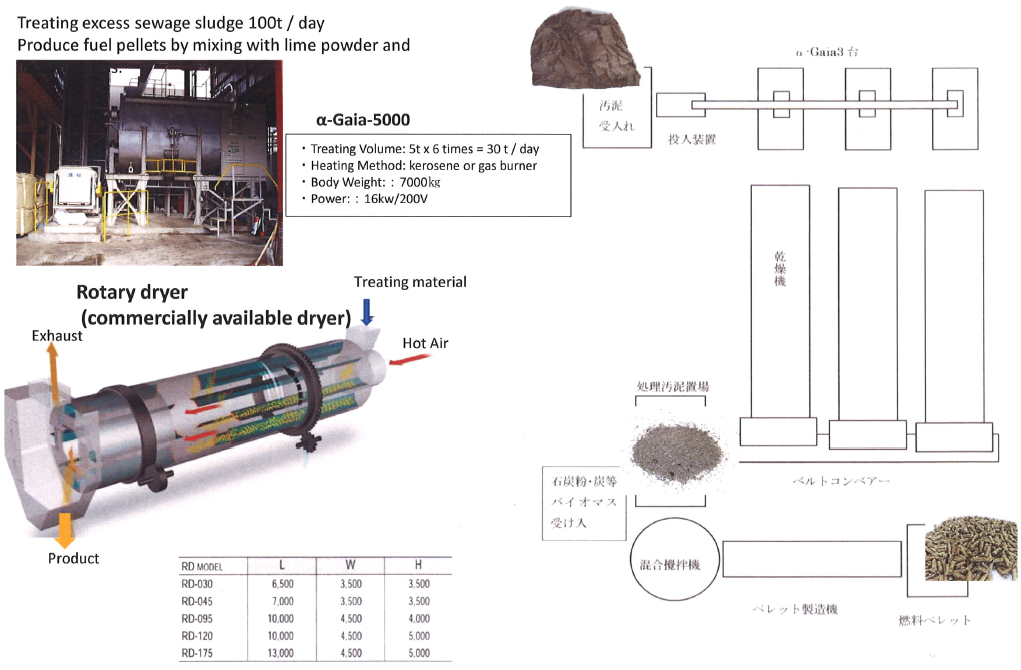

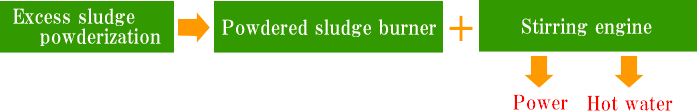

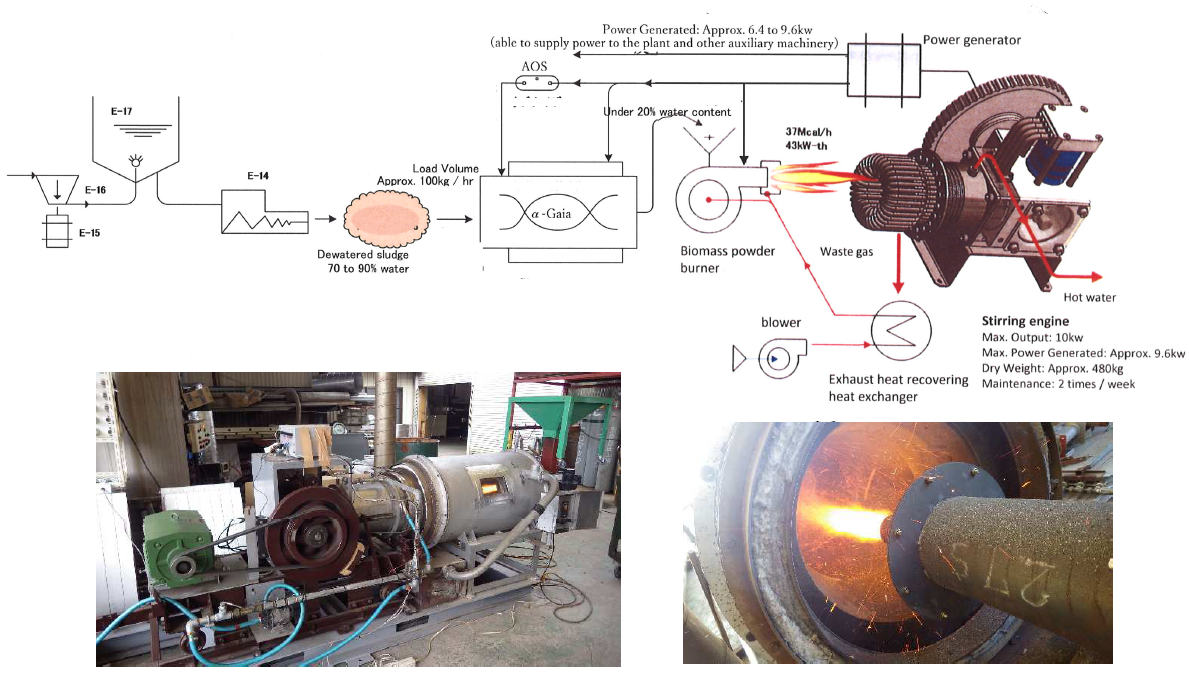

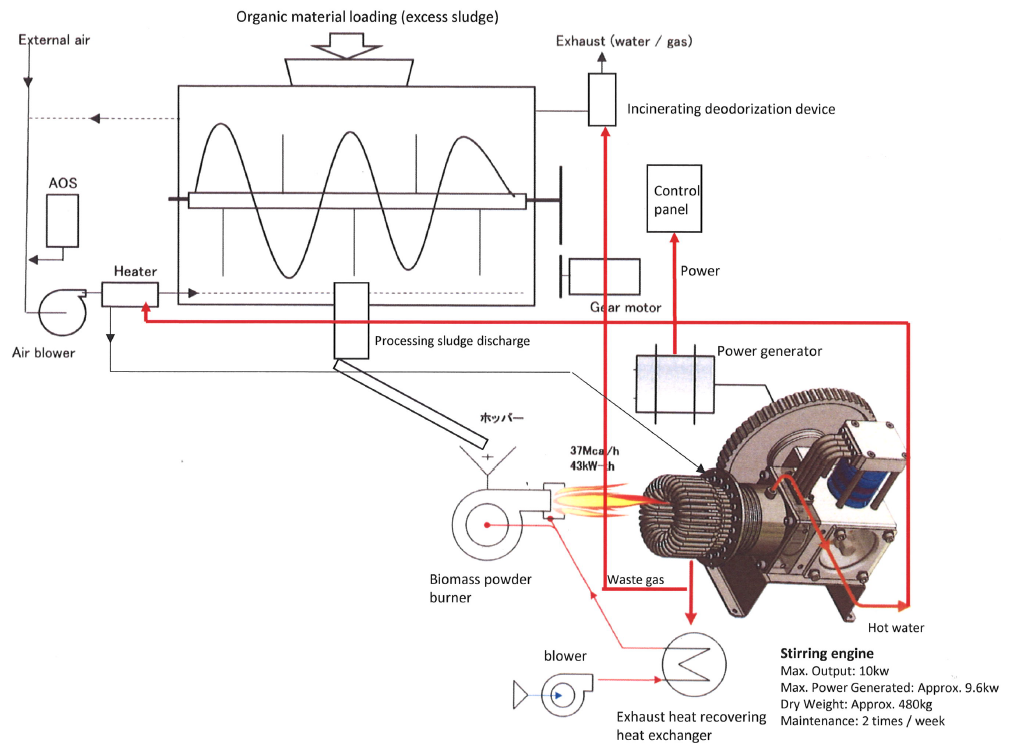

Powderization by α-Gaia Excess Sludge Treatment -> Fuel Production for Thermal Power Generation

- α-Gaia & AOS

-

-

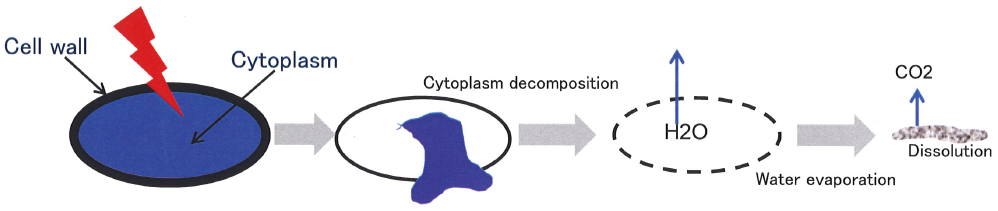

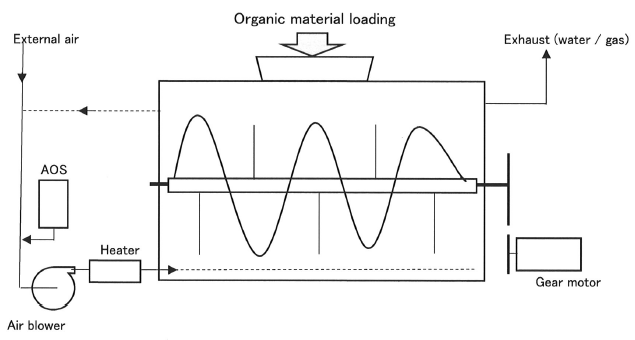

α-Gaia is the system to rapidly decompose, dry and powderize organic material by using air containing active oxygen produced by Air Operation System (AOS).

Active oxygen (particularly OH radical) has the highest oxidizing capacity on the earth. This means active oxygen is the best option for organic materials which will not decompose by any other methods. Our sludge treatment process effectively integrates this active oxygen.

-

α-Gaia is the system to rapidly decompose, dry and powderize organic material by using air containing active oxygen produced by Air Operation System (AOS).

- Air Operation System (AOS)

-

-

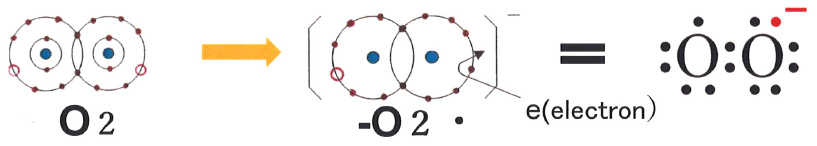

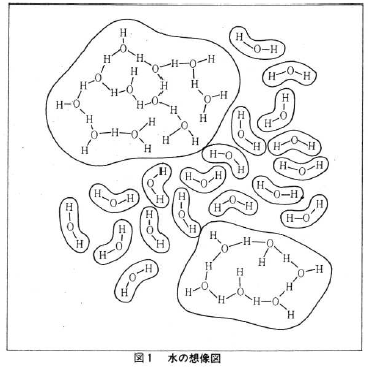

Like an ion engine for satellites, AOS consists of an ion generator and electron accelerator. The mechanism is quite simple as active oxygen and negative ions are accelerated to produce a very strong decomposition capacity.

Usage Consideration:

Advantage: The highest oxidation capacity on the earth

Disadvantage: Dissolves rapidly (1 to 6 millionths of a second)

-

Like an ion engine for satellites, AOS consists of an ion generator and electron accelerator. The mechanism is quite simple as active oxygen and negative ions are accelerated to produce a very strong decomposition capacity.

- α-Gaia Treatment for Organic Waste

-

-

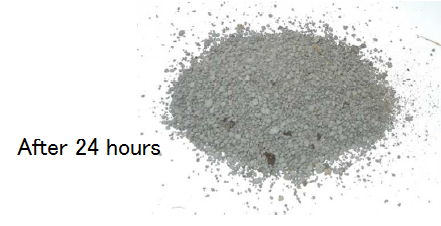

The α-Gaia system uses our world-leading technology to efficiently decompose and powderize organic material by reacting with active oxygen inside the treatment tank generated by AOS.

-

The α-Gaia system uses our world-leading technology to efficiently decompose and powderize organic material by reacting with active oxygen inside the treatment tank generated by AOS.

- Three Key Features of α-Gaia

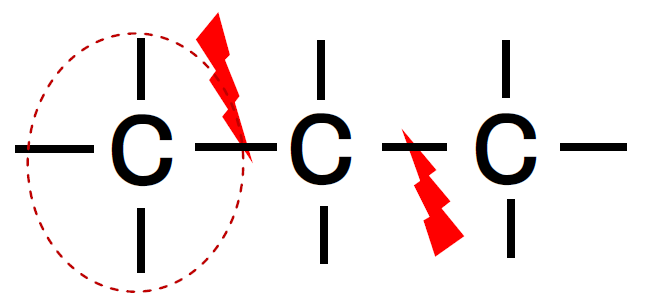

- Organic material is primarily composed of carbon bonds. This bond's powerful strength poses significant difficulty to the breakdown of cell membranes. Active oxygen, however, enables carbon bond breakdown relatively easily.

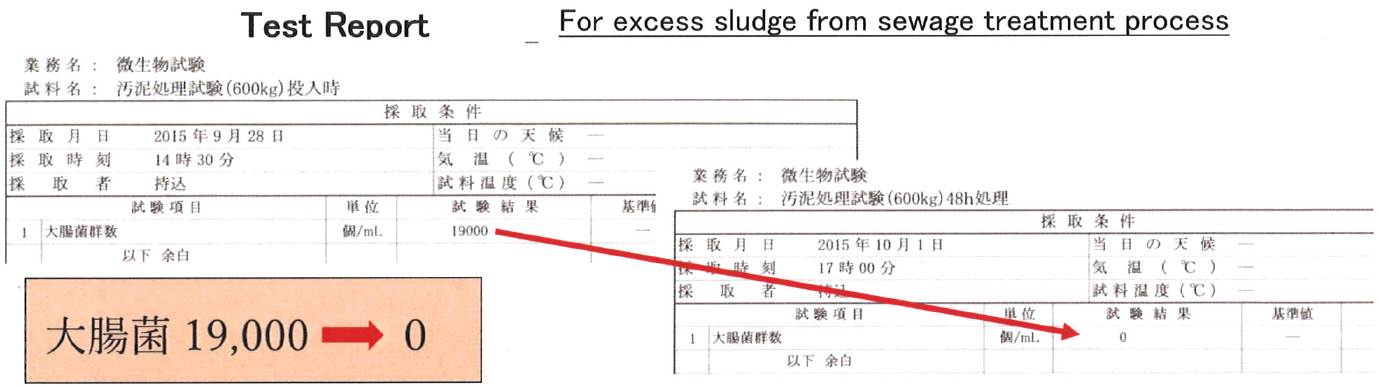

- Through such active air treatment processes, bacteria attached to organic material are also decomposed. Therefore, all bacteria are killed in the process.

1. Organic Substance Decomposition

Organic material treated by α-Gaia becomes micronized |

2. Promotion of Water Evaporation

The mechanism is not yet clear, but active air |

3. Antiseptic Effect

- Outline of α-Gaia

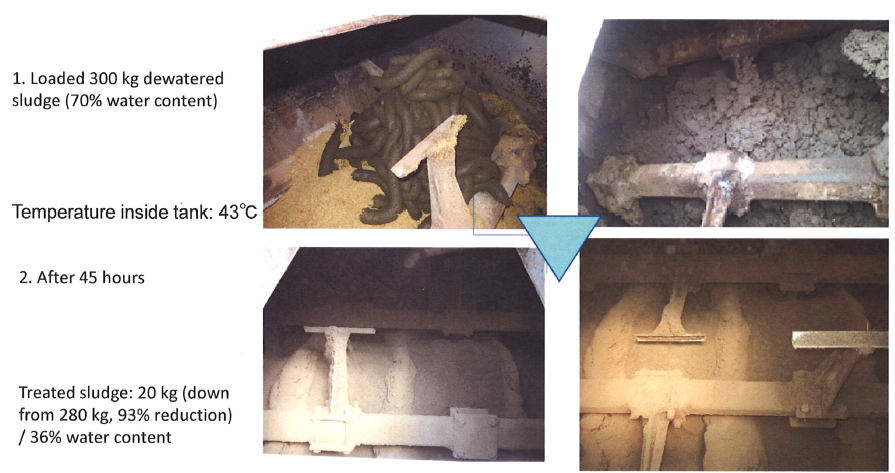

α-Gaia-100(capacity: 100㎏)

α-Gaia-2000(capacity: 2t)

Sewage sludge treatment test at the Konan Central Purification Center, Shiga Prefecture.

Factory wastewater & excess sludge treatment test

1. Active oxygen + heat treatment (100kg)

|

|

|

|

|

(clumping due to water from decomposed cytoplasm) |

(already significantly reduced) |

|

Start of process |

After 1 hour |

After 4 hours |

2. Only with heat treatment (50 kg)

|

|

|

*No changes in hot air condition from blower |

||

65 to 70% weight reduction |

||

Our technique of converting excess sludge into fuel

(for large amounts of sludge from sewage treatment)

Small amount sludge -> On-site power generation

α-Gaia: On-site excess sludge treatment system with hot water and power supply

Significantly reduces running costs for sewage and sludge treatment

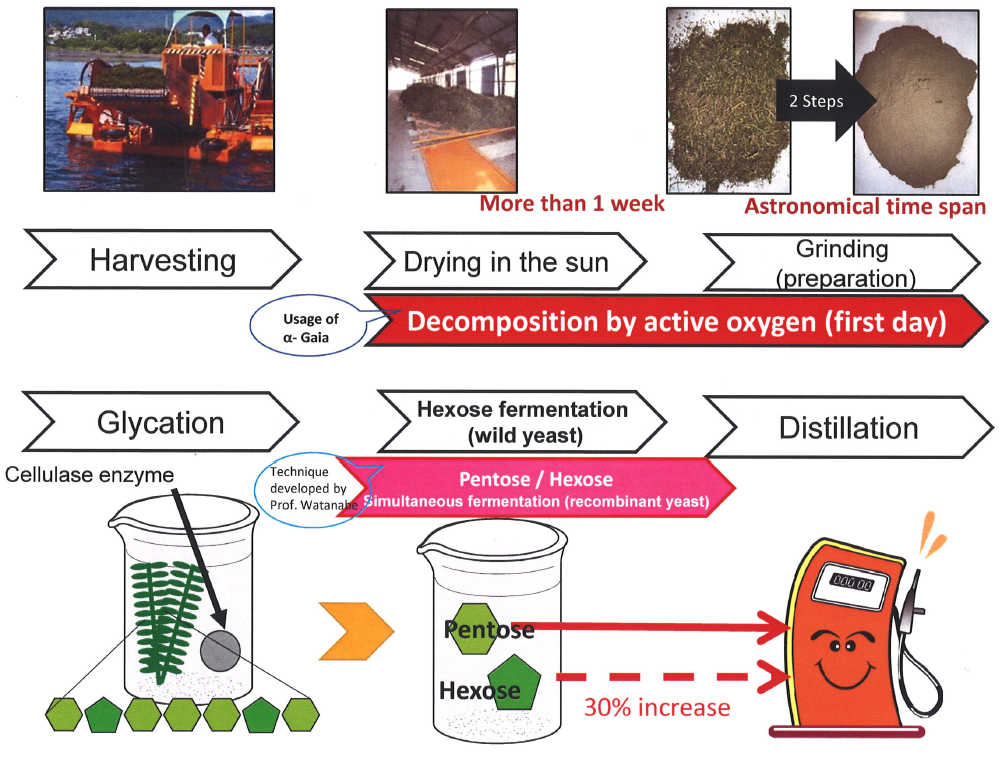

Ethanol from Waterweed: Powderization with α-Gaia allows great reduction of time to form ethanol

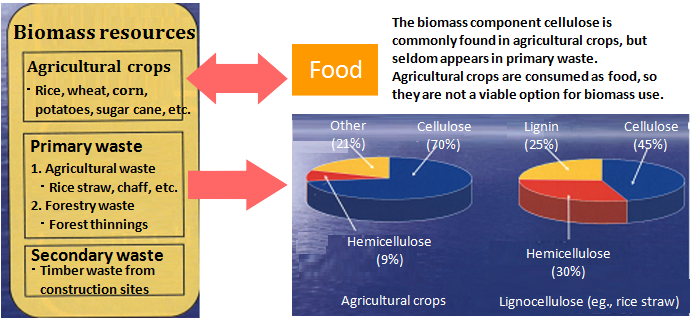

- Problems in forming ethanol from biomass

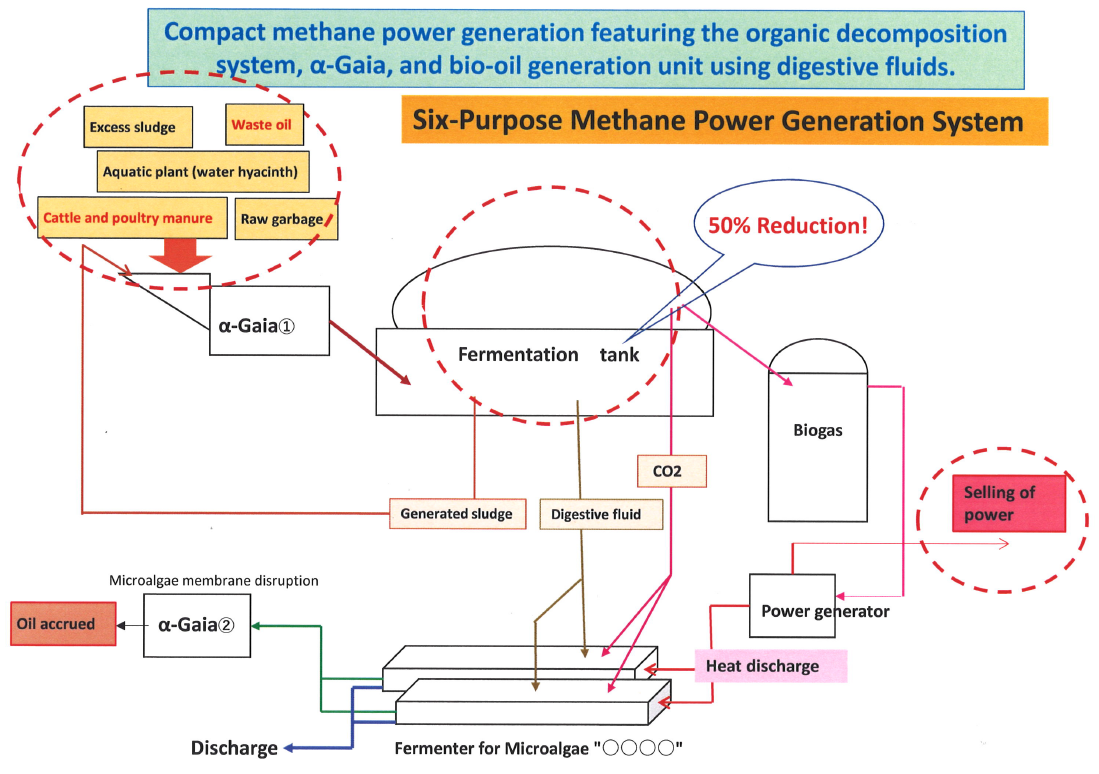

- A methane fermentation facility tends to be large because methane bacteria requires much time to break cell membranes of organic material for its nutrients. However, if the material's cell membranes can be broken prior to loading and processing, then the bacteria can obtain the nutrients much more quickly and therefore, the facility can be more compact.

- Landfill treatment has served almost exclusively as the major treatment method for disposing sludge waste. However, this method has several potential downsides such as significant operating costs for incineration and removal of harmful substances from the waste, as well as the enormous amount of energy used and gas generated. And yet, no one ever considered pursuing alternative approaches such as sludge waste recycling.

- CLIRAC solves problems of the conventional sludge waste treatment method while also allowing recycling and reuse of the treated material.

- Features of the CLIRAC Treatment Method

- CLIRAC Treatment Flow

- CLIRAC Method: Sludge Elution Test Result

- Mechanism for Coagulation & Dewatering

- Case Studies

Use of waterweed for ethanol formation: Collaborative research with Prof. Watanabe, Ehime University

High Efficiency Methane Fermentation (Compact Methane Power Generation Device)

CLIRAC Method: Insoluble Coagulation Treatment of Sludge

Easy, quick, economical, and safe way to treat organic and

inorganic sludge waste in coagulated form!

|

|

|

|

|

|

|

|

|

|

|

|

-

* No solidification material such as cement or caustic lime required.

| Safe & Stable Method : | Converts any type of sludge into harmless sandy soil. No re-sludging or re-elution of harmful substance. |

|---|---|

| High Capacity & Quick Treatment : | Solidifies sludge quickly regardless of initial water content. Solid enough to hold after just 1 hour into treatment. Does not revert into sludge ever again. Able to dewater completely under the sun in 4 to 10 days. |

| Volume Reduction : | Sewage sludge reduces down to one-tenth of the original volume (down to 10% water content) |

| Recycling Option : | No deterioration from gelation, heat or severe weather common for cement type solidification material Able to recycle as a base material for green landscaping such as slopes, lawns and parks. Treated petroleum sludge can be recycled as fuel since water completely dries out. |

| Final Product in Neutral State : | Treated and stabilized in a neutral state so no worry of secondary acid or alkali contamination. Therefore prevents harm to ecosystem or to fish and plant growth. |

◎ If targeting for maximum elution of a harmful substance,

increase the amount of CLIRAC coagulant agent according to the level

of contamination.

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

1. Excess Sludge (Dehydrated / 80% water content)

|

|

|

||

|

|

|

||

|

|

|

2. Excess Sludge (Precipitated / 98 % water content)

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

3. Petroleum Sludge (Generated from digging)

|

|

|

||

|

|

||||

|

|

|

||

|

|

|

|||