Water Treatment

Keyword Navigation

TERRAST & ASAL Processes for Heavy Metal Treatment

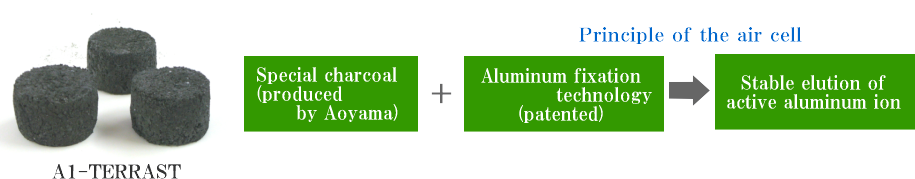

- TERRAST (Metallic Ion Elution Material):The World's Best Heavy Metal Treating Material

-

-

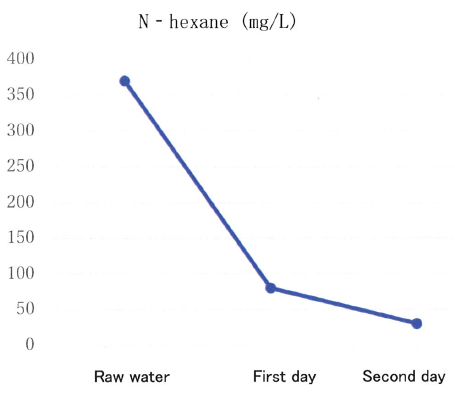

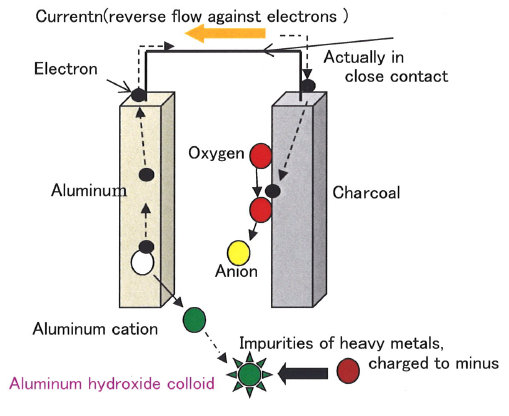

Because of a potential difference from air cell effect, current flows from charcoal to Al. As soon as aluminum cation is supplied to the water and causes hydrolysis, Al hydroxide colloid is generated.

Since this colloid is positively charged, impurities such as organic matter negatively charged in the aqueous solution are attracted electrically to the surface of Al hydroxide colloid, then attached and precipitated. -

- ASAL Process for Treating Wastewater from TERRAST Process

-

- TERRAST Variations

-

In treating phosphorus and arsenic, Fe-TERRAST has shown better capability than Al-TERRAST does.

Plantlife requires ferric iron for growth. Even in nutrient-rich environments, they will not thrive without it. This explains why few phytoplankton exist in the Antarctic Sea where they cannot take enough ferric iron into their system. -

A type of ion necessary for plant growth.

Effective for treating suspended solids in water. - Effective for quantitative sterilization.

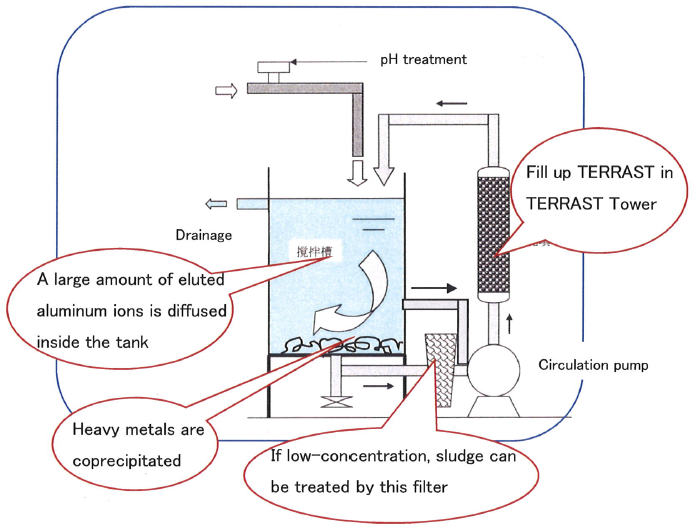

<ASAL Process Features>

・Treat almost ANY type of inorganic residues, such as heavy metals, silica, fluorine, etc.

・Practice a low-concentration treatment (coagulation power does not decline)

・Cut down an initial cost by easy installation to your existing facilities.

・Low running cost since TERRAST is only filled every 6 months.

<ASAL Installation Examples>

|

|

|

Boron Treatment |

Antimony Treatment |

Fluorine Treatment |

・Fe-TERRAST

|

|

|

| Fe-TERRAST usage resulted in death rate reduction among shellfish, which had been 30% but by the second year was reduced to 0%. | ||

・Mg-TERRAST

・Cu-TERRAST

For this reason, high levels of arsenic are detected in groundwater of areas in some parts of China, India, Bangladesh, Cambodia, Laos, Vietnam, Thailand and Myanmar.

Fe-TERRAST is very effective for treating such arsenic contaminated groundwater. We have already done on-site testing in Bangladesh and Vietnam.

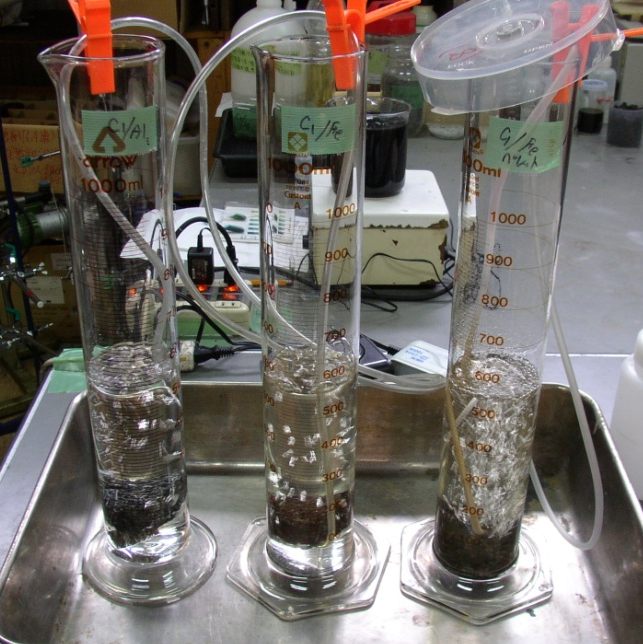

Beaker Test

|

|

|

|

|

|

|

|

|

|

|

|

(left to right: charcoal & Al TERRAST block, charcoal & Fe-TERRAST, and charcoal & Fe-TERRAST pellet) |

|

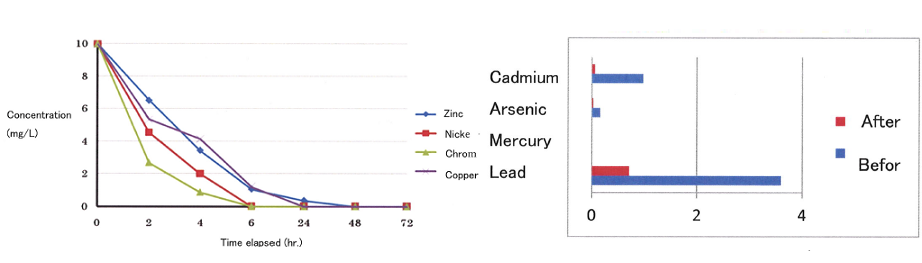

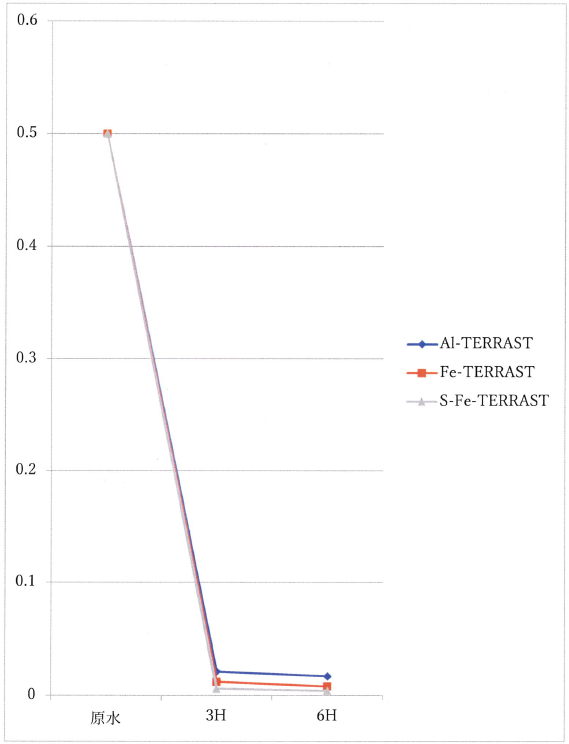

| Arsenic Treatment | Raw water | 3H | 6H |

|---|---|---|---|

| Al-TERRAST | 0.5 | 0.021 | 0.017 |

| Fe-TERRAST | 0.5 | 0.012 | 0.007 |

| S/Fe-TERRAST | 0.5 | 0.006 | 0.004 |

Tested at a Bangladesh University

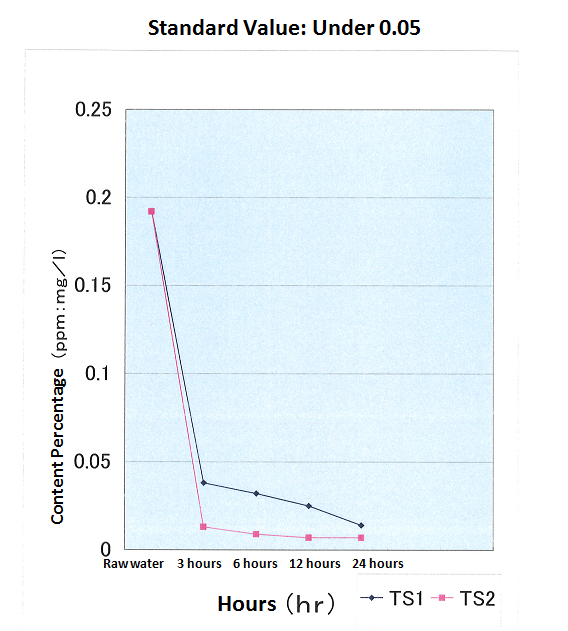

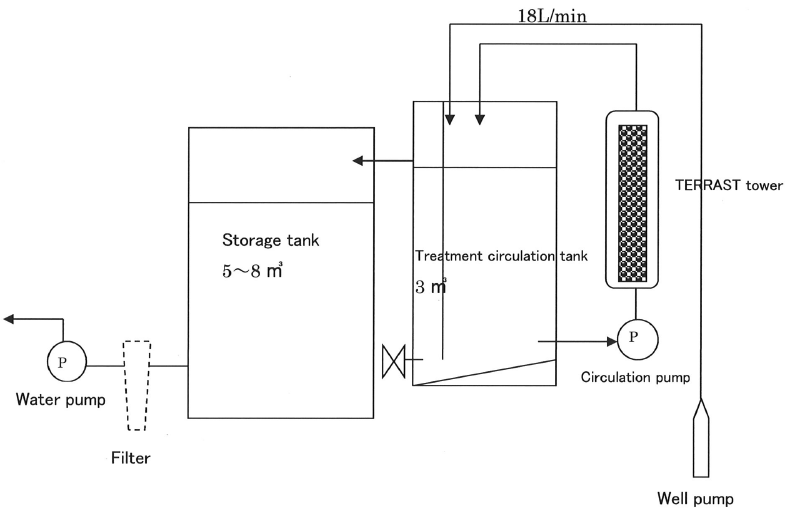

Arsenic Treatment System

|

1. Treating Condition ・Water throughput: 10?/12 hrs. ・Raw water arsenic level: approx. 0.3㎎/L ・?理?度:0.05mg/L以下 |

・Treatment tank size: 3? ・Circulation pump: 150L/min×40A ・Water throughput (well pump): 18L/min |

Treatment Process Flow

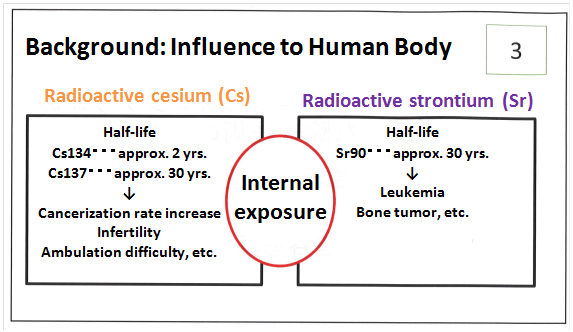

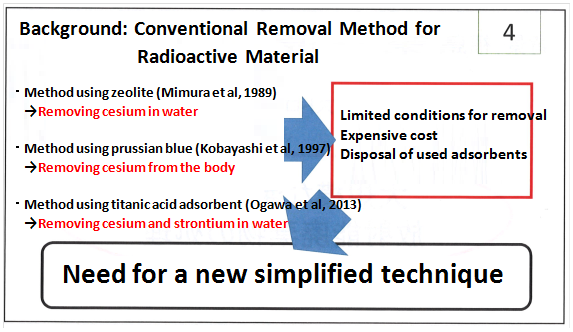

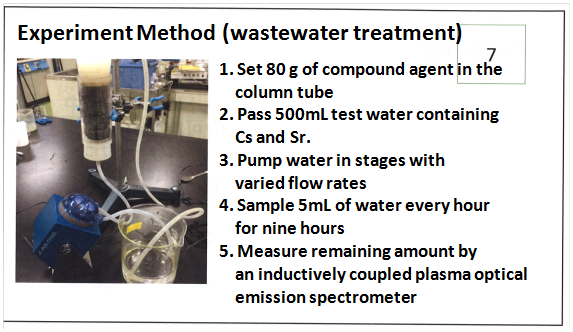

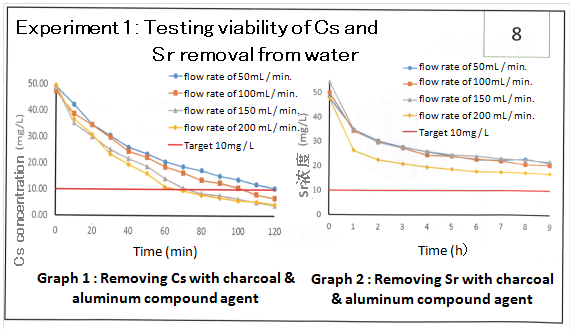

At the Fukushima Daiichi Nuclear Power Station accident caused by the Tohoku Region Pacific Coast Earthquake, a vast amount of radionuclides was released into the air. Consequently, the environment of eastern Japan was contaminated by radiation. Dispersion of radioactive materials occurred not only at the directly affected area, but also other areas due to transportation of goods. One significant issue of this incident is the continuation of marine pollution even after three years, and of radioactive contamination to populated cities including the Tokyo Metropolitan area, and radionuclides reaching forest ecosystems.

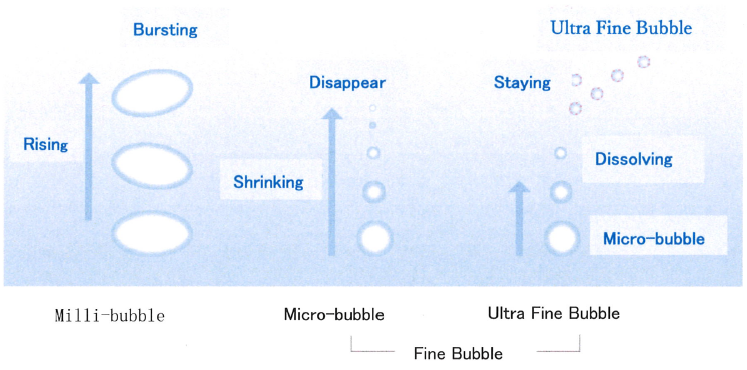

Ultra Fine Bubble Generator (UFB)

Micro-bubble retention in water

- Ultra fine bubbles can stay in water without rising to the surface, and hence can be used to activate microbes in the water, improving anaerobic conditions at the bottom and eliminating odor.

UFB generator

UFB-A Model When combined with an oxygen generator, this model can effectively supply highly concentrated oxygen into water. This enables blower energy reduction and sludge reduction during activated sludge water treatment. |

UFB-B Model When using this model for purifying rivers, canals and lakes, microbes in water and bottom soil can be activated to improve natural depuration of the environment. |

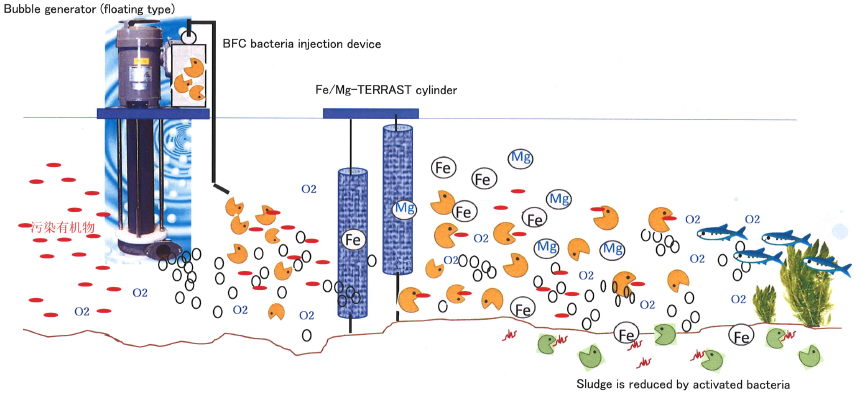

River / canal / pond purification

Our system revitalizes the natural purification capability of rivers and canals, using fine-bubble + BFC Bacteria + Fe-TERRAST + Mg-TERRAST. *BFC Bacteria: bacillus dedicated to our developed water treatment system.

Pond purification test in Wuxi, China

-

3 units of USB-B, 3,000 pcs of Fe-TERRAST, and 3,000 pcs of Mg-TERRAST

Test started in January, 2017

|

|

|

|

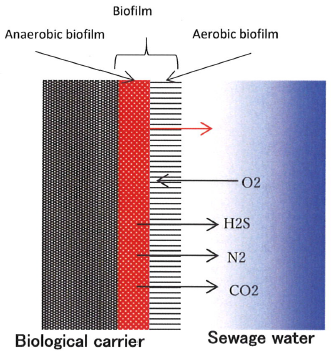

SBC Contact Material (mounted type microbe carrier)

|

|

|

|

|

Structural Characteristics

・Specific surface area of filtering media is large (60 to 100㎡/?)

・Filling rate of filtering media is high (70 to 80 %)

・Volume load can be increased (volume load of fixed filter is from 0.6 to 1.2㎏BOD/?・d)

Benefits of the Process

・Enables effective treatment by encouraging cohabitant of anaerobes and aerobes.

・No sticking or clogging as seen with other contact material types (no cleaning is required)

・Reduces excess sludge

|

|

|

Dissolving dimethylformamide (DMF) from factory exhaust into water and then conducting SBC treatment |

|

|

|

|

Wastewater treatment at a chemistry plant. No sludge for 20 years. |

|

Patented in Japan, China and Taiwan. |

|

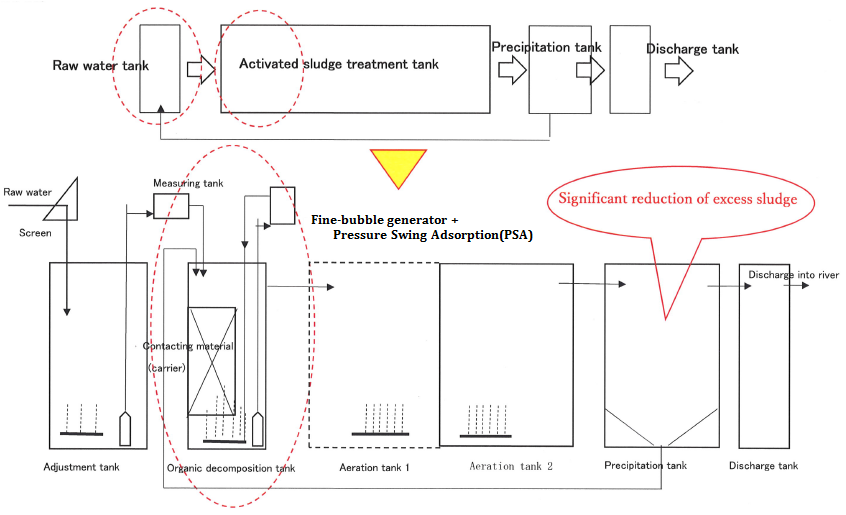

SBC Contacting Material + UFB + BFC Bacteria

-

Change a raw water adjustment tank or activated sludge treatment tank to organic decomposition tank.

*Pre-treating material with a rapid organic decomposition process is highly recommended in order to reduce costs. Adding micro-bubble or BFC bacteria into the biological treatment tank without any pre-treatment is possible, however it can increase running costs.

Test equipment

|

|

-

Pre-treatment with oil decomposition process is essential for wastewater from food or grease factories, because significant amounts of oil may cause dysfunction of the treatment system. A pressurized flotation separation device has been commonly used for separating grease. However, the separated oil in this method is treated as industrial waste, and may cause problems such as bad odor and contamination of treatment equipment.

SBC Treatment enables compact, low-maintenance operation through the standard activated sludge method.

Oil decomposition test

|

|

|

|

|

|

Analysis data